Hello, my fellow artisans and craftsmen! Welcome to darlenemccoy.com, where the art of machining finds its voice. I am Sarah, a master engineer and machinery consultant, here to share with you the secrets of craftsmanship.

Today, let us embark on a harmonious journey into the world of stainless steel carriage bolts, where the melody of their benefits enchants us all.

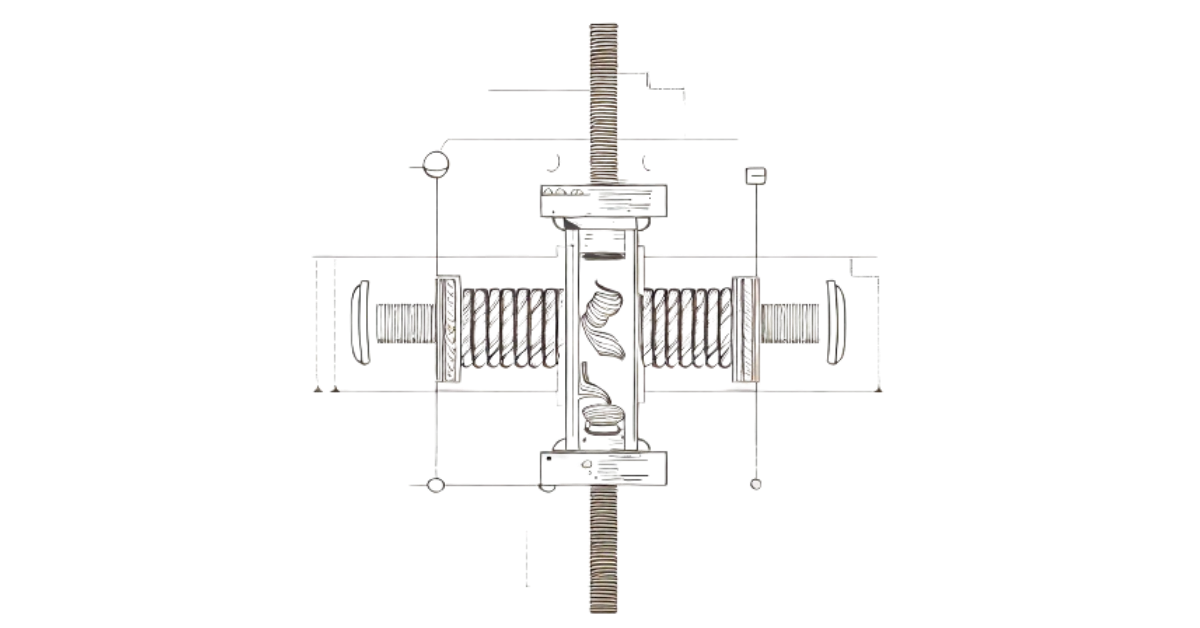

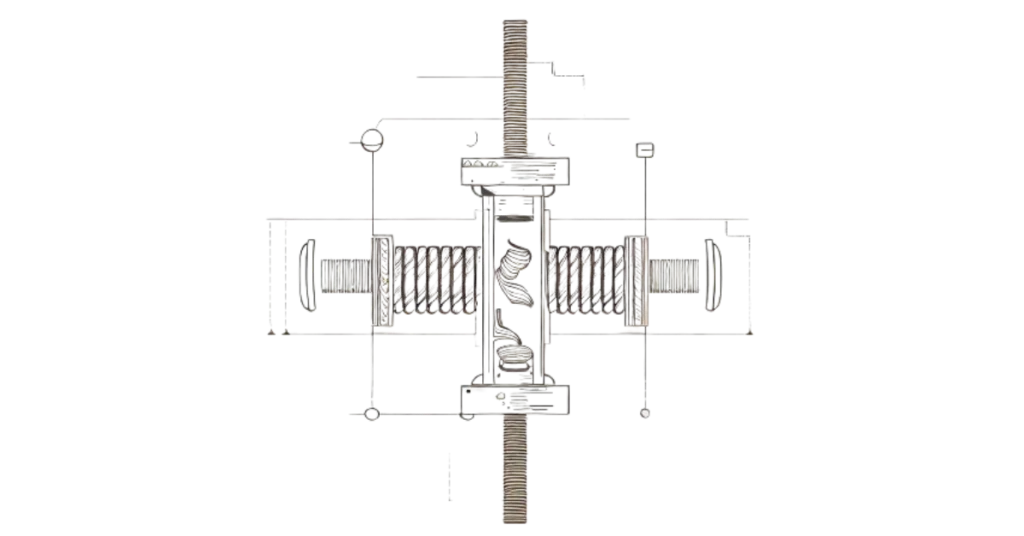

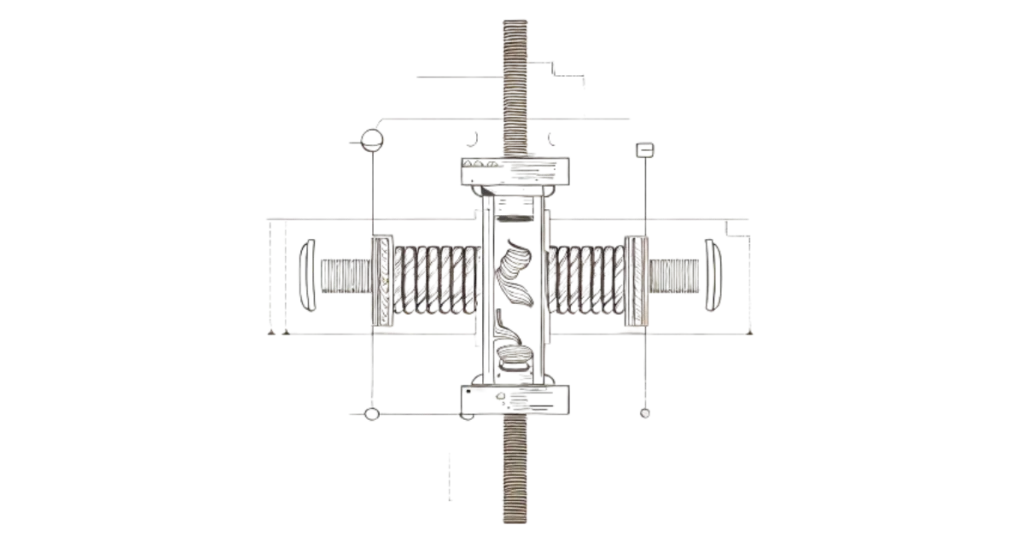

Carriage bolts, also known as plow bolts or coach bolts, have graced our projects with their round heads and square necks. These fasteners elegantly prevent bolts from turning when tightened, a delightful feature when only one side of the bolt is accessible. Carriage bolts join wood, metal, plastic, and other materials together, serenading us with their versatility.

In this symphony of knowledge, we shall explore the virtues of stainless steel carriage bolts. Why do they stand tall among other fasteners? What advantages do they offer to elevate our creations? Join me as we journey through the following movements:

- The properties and characteristics of stainless steel carriage bolts

- The benefits of using stainless steel carriage bolts for different applications

- The best practices and tips for using stainless steel carriage bolts

When the final note echoes, you will be well-versed in the melodious benefits of stainless steel carriage bolts and how to use them properly and safely in your masterpieces. Let the overture begin!

The Properties and Characteristics of Stainless Steel Carriage Bolts

Stainless steel carriage bolts waltz in with grace, their composition setting them apart. These bolts are crafted from steel infused with chromium, nickel, and other elements, bestowing them with corrosion resistance, strength, and durability. Often referred to as inox steel or inox, derived from French inoxydable, meaning “inoxidizable”¹, stainless steel shines with its unmatched properties.

Dancing to different grades, stainless steel carriage bolts express their unique characteristics:

18-8

A symphony of 18% chromium and 8% nickel, 18-8 stands as the most widely used grade of stainless steel for general purposes. Its remarkable corrosion resistance, strength, and ductility make it a virtuoso in various applications. It can brave temperatures up to 1500°F (816°C)², adding a touch of versatility to its sonata.

304

A harmonious blend of 18% chromium, 8% nickel, along with small amounts of carbon and manganese, 304 resonates closely with 18-8. However, it dances with slightly better corrosion resistance and weldability, enduring temperatures up to 1600°F (871°C)² with finesse.

316

The grand conductor of stainless steel, 316 boasts 16% chromium, 10% nickel, and 2% molybdenum in its symphony. Similar to 304, it embraces better corrosion resistance and strength, especially in acidic and marine environments. It unfalteringly withstands temperatures up to 1700°F (927°C)², lending itself to the most challenging of crescendos.

As these stainless steel carriage bolts take center stage, they showcase their smooth, round heads and square necks. The heads sit flat on the material’s surface, while the square necks fit snugly into square holes or recesses, gracefully preventing turning when the nut is tightened.

Carriage bolts offer a grand variety of sizes, from #10 to 3/4 inch in diameter and from 1/2 inch to 20 inches in length³. They also wear different finishes, such as plain, zinc-plated, or black oxide³, accentuating their appearance and corrosion resistance.

The Benefits of Using Stainless Steel Carriage Bolts for Different Applications

As our symphony reaches its crescendo, let us revel in the myriad of benefits that stainless steel carriage bolts bring to our projects:

Corrosion Resistance

In the face of the tempestuous elements, stainless steel carriage bolts stand unyielding. Their resistance to rusting, tarnishing, pitting, staining, or cracking makes them a celestial choice for outdoor or harsh environments. From decks and docks to fences and boats, they sing with resilience in bridges and buildings.

Strength

With unwavering strength, stainless steel carriage bolts form the foundation of heavy-duty or structural applications. Furniture, playground equipment, railings, stairs, and roofs all dance gracefully with these stalwart bolts, confident in their ability to endure high levels of stress and pressure without faltering.

Durability

The grand sonata of durability plays on as stainless steel carriage bolts march through the passage of time. They stand the test of years, maintaining their quality and performance, bringing lasting harmony to locks, hinges, gates, and signs.

Versatility

Ah, the crescendo of versatility! Stainless steel carriage bolts join the dance of various materials, embracing wood, metal, plastic, concrete, and more in their embrace. Whether combined with washers and nuts or gracing components solo, they create a symphony of security and stability.

Appearance

With their smooth and sleek finish, stainless steel carriage bolts add an enchanting touch to the aesthetics of your project. They complement the colors and textures of the material or provide a striking contrast, leaving an indelible mark on your creation.

The Best Practices and Tips for Using

Stainless Steel Carriage Bolts

Now, my fellow artisans, let us delve into the secrets of using stainless steel carriage bolts to ensure a harmonious masterpiece:

Choose the Right Size, Type, and Grade

In this symphony of craftsmanship, selecting the correct size, type, and grade of stainless steel carriage bolt is paramount. The bolt should match your project requirements precisely, avoiding the discord that arises from mismatched bolts.

Drill Holes with Precision

As we strike the chords of precision, drilling holes slightly larger than the bolt’s diameter ensures a seamless fit. Measure the diameter of your bolt with a caliper or ruler and choose an appropriate drill bit. Align the holes on both components evenly, using a pencil, marker, or center punch to mark the drilling spots.

Secure Components During Drilling

To keep the rhythm steady, clamp or secure your components during drilling. This prevents shifting or movement that could lead to offbeat holes and misaligned connections. Embrace clamps, vices, screws, nails, or any other means to hold your components in place while you work.

Drill Slowly and Steadily

As the symphony progresses, use an electric drill, a hand drill, or a drill press to drill your holes. Begin with a small pilot hole, gradually enlarging it with a larger bit. Drill slowly and steadily, applying even pressure while keeping the drill perpendicular to the workpiece. Pause frequently to check alignment and clear out debris or chips.

Insert and Assemble Gracefully

In a graceful cadenza, insert the bolt through the hole, ensuring the head aligns with the side where you intend to tighten the nut. Let the square neck nestle into its designated square hole or recess. If the fit is snug, embrace a gentle tap from a hammer to bring everything into perfect alignment.

Adding Washer and Nut

In this harmonious union, bring the washer and nut to the stage. Slide the washer onto the threaded end of the bolt, followed by the nut. The washer distributes the load evenly, protecting the material from the bolt’s pressure. The nut stands as the conductor, orchestrating a symphony of clamping force between the components.

Tighten with Grace

With the final crescendo drawing near, it is time to tighten the nut. With only one side of the bolt accessible, the square neck ensures no turning during the tightening process. Apply a wrench, a ratchet, or a socket to the nut, tightening until it is snug and firm, without overstraining the bolt.

Avoiding Common Mistakes

As we reach the grand finale, let us avoid the pitfalls that may lead to disharmony. Be mindful of using the correct size, type, and grade of stainless steel carriage bolt. Drilling holes that are too large or too small, misaligned or uneven, can lead to a dissonant connection. Overtightening or undertightening the nut may likewise disrupt the harmony.

Conclusion

As the final chords echo, we bask in the resplendent benefits of stainless steel carriage bolts. Their corrosion resistance, strength, durability, versatility, and aesthetics are the hallmarks of a true virtuoso. In furniture, decks, docks, fences, playground equipment, and beyond, these bolts shine brightly, conducting the symphony of craftsmanship.

Remember, my fellow artisans, to choose wisely the size, type, and grade of your stainless steel carriage bolts. Drill with precision and grace, securing your components during the process. Assemble with care, embracing washers and nuts in their role as protectors and conductors. And above all, avoid the common mistakes that could lead to discord in your masterpiece.

I hope this symphony has enlightened you on the benefits of stainless steel carriage bolts and how to use them properly and safely. If you have any questions or desire to share your harmonious creations, leave your thoughts below. Let us continue our journey, each note a step towards craftsmanship’s crescendo.

Thank you for your presence in this symphony of craftsmanship. Until we meet again, may your projects resonate with the timeless beauty of stainless steel carriage bolts. Farewell, dear readers, farewell!