Greetings, my dear craftsmen and craftswomen! I am Sarah, a master engineer and machinery consultant, and I bid you welcome to darlenemccoy.com, where the secrets of machining products are unveiled. Today, I shall regale you with the fascinating history and evolution of carriage bolts, those magnificent fasteners that have stood the test of time.

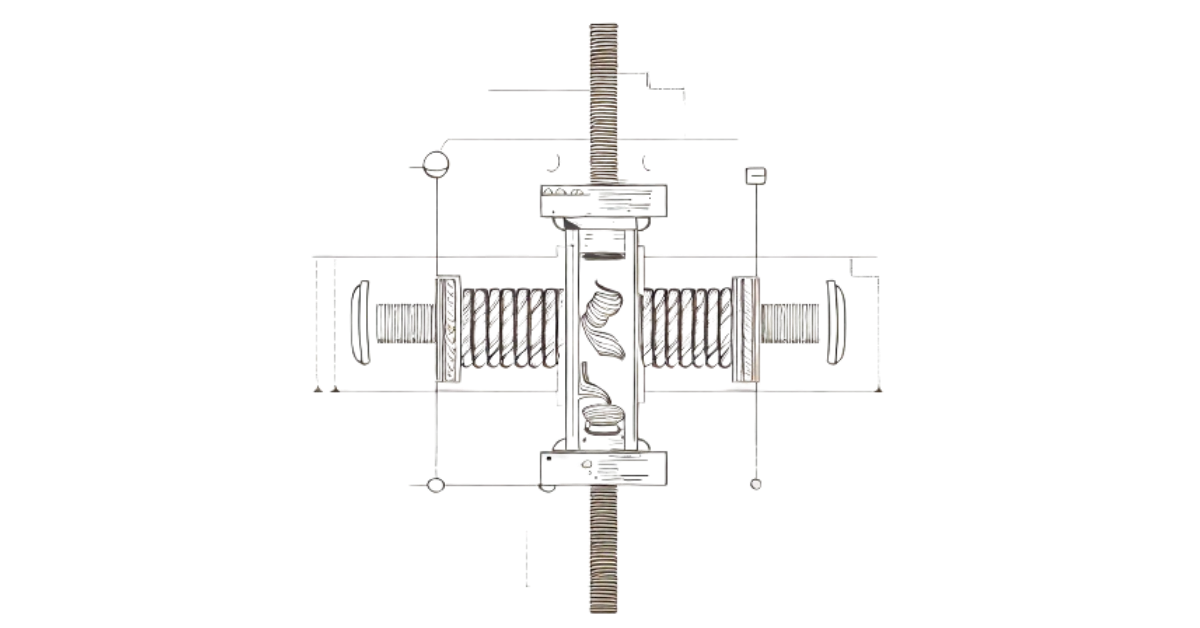

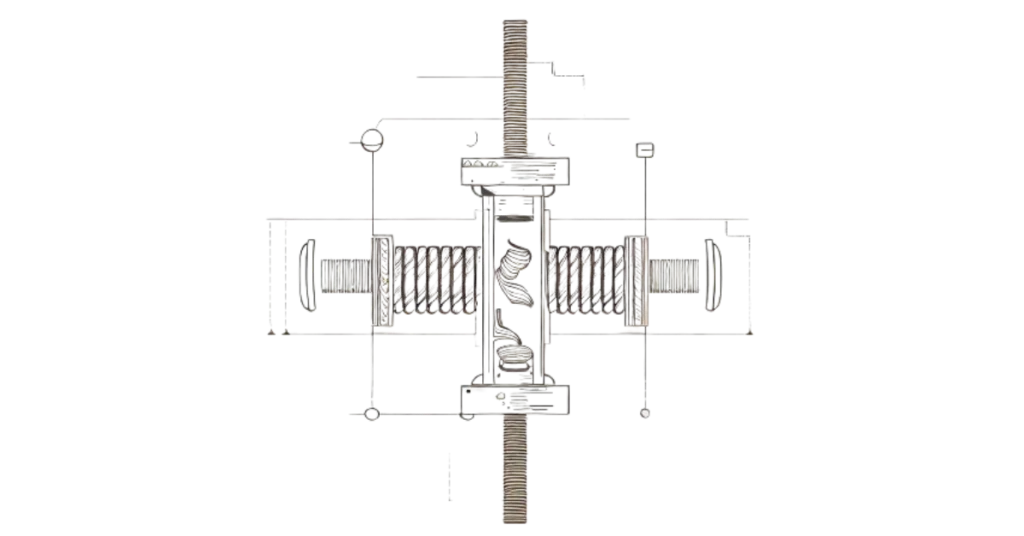

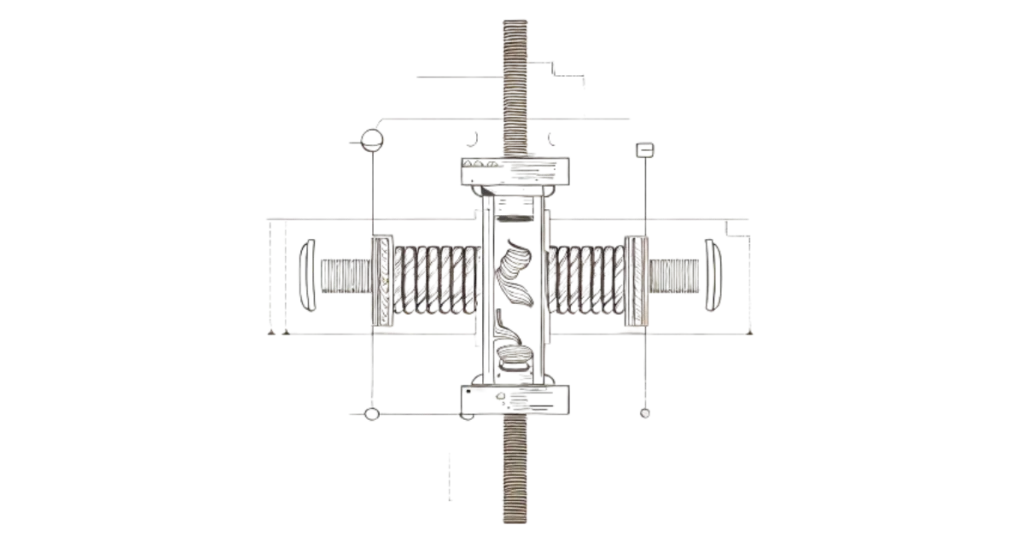

Carriage bolts, also known as plow bolts or coach bolts, are a true marvel of engineering. With their round heads and square necks, they possess a unique ability to prevent rotation when the nut is tightened, making them a prized possession in applications where only one side of the bolt is accessible. These versatile fasteners have graced the construction of wood, metal, plastic, and other materials, joining them harmoniously to form magnificent creations.

In this musical tale of craftsmanship, we shall journey through time and explore the following themes:

- The origins and early use of carriage bolts.

- The symphony of different types and variations of carriage bolts.

- The modern applications and the sweet melodies of their advantages.

- A delightful serenade of interesting facts and trivia about carriage bolts.

By the final note, you shall possess a profound understanding of the history and evolution of carriage bolts, leaving you inspired to embrace these magical fasteners in your own symphony of craftsmanship. So, let the performance begin!

The Invention and Early Use of Carriage Bolts

The story of carriage bolts stretches back through the annals of history, where they first emerged as essential elements in the construction of carriages and carriage wheels. It was in the small town of Marion, Southington Township, Connecticut, that the renowned blacksmith Micah Rugg breathed life into these fasteners in the year 1818¹. As for the origin of the term “carriage bolt,” it remains shrouded in mystery. Some speculate it might stem from the Old French word ‘cariage,’ not referring to vehicles, but rather related to the English word ‘carry’².

With their round heads and square necks, carriage bolts were perfectly suited to hold together wood with metal or metal with metal through a square hole in a metal strap. The square neck’s magic lay in its ability to prevent the bolt from turning during the tightening process, a valuable feature in applications where one side of the bolt remained out of reach.

Yet, these extraordinary fasteners were not content to confine their brilliance to carriages alone. They soon found themselves playing pivotal roles in diverse scenarios, including agricultural implements, railway tracks, bridges, ships, and buildings. During the Industrial Revolution, their influence soared, as they facilitated the mass production and transportation of goods and materials, harmonizing with the spirit of progress.

The Symphony of Different Types and Variations of Carriage Bolts

As the symphony of craftsmanship unfolded, the original carriage bolts diversified into a harmonious ensemble of different types and variations, each tailored to suit specific needs and applications. Let us immerse ourselves in the melodic arrangements of these delightful variations:

Roundhead and Rib-necked Bolts

Ah, the sweet serenade of roundhead and rib-necked bolts. With their round heads adorned with ribs or serrations beneath, these bolts found their calling in wood-to-wood connections. The ribs masterfully grip the material, ensuring steadfastness against the dissonance of vibration or movement.

Roundhead and Short-necked Bolts

In the grand orchestra of metal-to-metal connections, the roundhead and short-necked bolts danced with finesse. Their short square necks, elegantly shorter than the diameter of the shank, ensured seamless harmony with the surrounding design.

Flathead and Square-necked Bolts

As the maestros of flush finishes and limited spaces, flathead and square-necked bolts took the stage. Their flat or countersunk heads, aligning with the material surface, showcased a flawless visual symphony, a testament to their versatility.

Fin Necked Bolts

In the realm of plastic and composite materials, fin necked bolts showcased their mastery. Their round heads, accompanied by delicate fins or projections beneath, established a firm grip on the materials, effectively preventing unwanted rotation.

Like the notes in a mesmerizing melody, carriage bolts vary in size, material, finish, and grade, further enriching their repertoire. They present an awe-inspiring range, from #10 to 3/4 inch in diameter and 1/2 inch to 20 inches in length³. The materials of their composition, be it steel, stainless steel, brass, bronze, aluminum, or even plastic³, compose a symphony of possibilities. And like a conductor guiding the orchestra, the choice of finish, such as zinc, black oxide, or stainless steel³, sets the tone for the final masterpiece. Finally, the grades, denoting strength and durability³, infuse the

fasteners with varying degrees of resilience.

The Modern Applications and the Sweet Melodies of Their Advantages

The symphony of carriage bolts continues unabated in the modern era, where they find themselves serenading various applications. From furniture to decks, docks to fences, playground equipment to more, the versatility of carriage bolts knows no bounds. Their advantages chime in harmoniously, making them beloved components in numerous creations:

Self-Locking

As the conductor raises the baton, the square section of the shank takes the stage, seizing the spotlight with its self-locking prowess. This marvelous feature allows the bolt to resist turning during installation, rendering the fastener a one-wrench wonder.

Low-Profile Head

In the grand concert of finishes, the rounded head leads the melody with elegance. Its low-profile nature not only presents a cleaner appearance but also minimizes the risk of snagging or injury when working with the bolted material.

Versatility

Ah, the grand cadenza of versatility! Carriage bolts weave their magic in a myriad of materials, including wood, metal, plastic, concrete, and more. An ensemble that harmonizes seamlessly with diverse materials, making it the ideal choice for various projects.

Strength

As the crescendo rises, the strength of carriage bolts shines through. Their varying types and grades sing a song of resilience, enabling them to endure high levels of stress and pressure without yielding.

Some Interesting Facts and Trivia About Carriage Bolts

Ah, my dear craftsmen and craftswomen, let us now savor some fascinating facts and trivia about carriage bolts:

- The largest carriage bolt ever made was a true titan of fasteners. Measuring a whopping 20 feet in length and 10 inches in diameter, it played a critical role in holding together a wooden bridge in Pennsylvania in the year 1841⁴. Truly a sight to behold!

- Our journey through time takes us to the 16th century, where a Frenchman named Besson invented the first machine for manufacturing nuts and screws in the year 1568⁵. However, it wasn’t until the 18th century that standardized sizes and threads made their melodious debut⁵.

- The term “bolt” itself carries a legacy that spans back to the Old English word “bolt,” meaning “arrow” or “dart.” Yes, my friends, bolts were originally used as projectiles in crossbows and catapults, adding a touch of historical intrigue to their symphony⁶.

- And let us not forget the “nut” in our fastener concerto. The term “nut” comes from the Old English word “hnutu,” which delicately translates to “hard seed.” For indeed, the early nuts were crafted from hard seeds or fruits, such as acorns or walnuts⁶. A delightful morsel of trivia, wouldn’t you say?

Conclusion

As the symphony of craftsmanship draws to a close, we find ourselves enchanted by the captivating history and evolution of carriage bolts. From their humble beginnings in carriage construction to the modern-day applications that shape our world, these fasteners have proved themselves timeless and indispensable.

Their journey through time has witnessed an evolution of types, sizes, materials, and finishes, ensuring they can harmonize with any project’s needs. The advantages they bring, from self-locking to low-profile heads, only serve to enhance their allure. And with their strength and versatility, they continue to earn a rightful place in the hearts of craftsmen and craftswomen worldwide.

So, my fellow artisans, as you embark on your crafting endeavors, let the symphony of carriage bolts echo in your creations. Embrace their history, appreciate their evolution, and allow their melodies to shape your masterpieces. May you find inspiration in their storied past and create a future filled with craftsmanship’s sweet harmony.

And now, my dear readers, the stage is yours. If you have questions or comments about the captivating world of carriage bolts, let your voice be heard below. Share your experiences, and let us celebrate the grand symphony of craftsmanship together.

With heartfelt thanks for your attendance and a final bow, I bid you farewell till our next melodious encounter.

FAQs

Ah, the encore of our symphony, where curiosity takes center stage. Allow me to address your inquiries with the utmost delight:

Where can I find carriage bolts?

Carriage bolts await your discovery in various hardware stores, both local and online. Delight in the expertise of knowledgeable staff at local establishments or explore the vast digital realm of online retailers, where a cornucopia of carriage bolts awaits your selection.

Can carriage bolts be used in outdoor projects?

Indeed, they can! Carriage bolts, especially those made of stainless steel or brass, serenade outdoor projects with their corrosion resistance. Whether amidst nature’s elements or in the embrace of an indoor sanctuary, carriage bolts offer their harmonious touch.

Are carriage bolts reusable?

Ah, a melodic question indeed! Carriage bolts can be reused under certain circumstances, but like any virtuoso performer, they require careful inspection for signs of wear or damage. Listen to their subtle cues, and if they retain their structural brilliance, they may grace your symphony once more.

Can I use carriage bolts for metal-to-metal connections?

Of course! With their versatile range of types and sizes, carriage bolts can take center stage in metal-to-metal connections, joining their melodious heads and square necks in harmonious union.

5. Are carriage bolts tamper-resistant?

Ah, the security of craftsmanship! Yes, indeed, the square neck beneath the head adds a layer of tamper resistance, making it a challenge for unauthorized hands to remove the bolt without access to the nut. A true testament to the reliability and security of these captivating fasteners.

With the final cadence of questions answered, we bring our symphony to a close, leaving behind a legacy of craftsmanship’s sweet harmony. Till we meet again, let your crafting endeavors continue to dance with the magic of carriage bolts, and may each creation compose a masterpiece of its own. Farewell, dear readers, farewell!