Howdy, folks! This is Sarah, a master engineer and machinery consultant, here to share some bluesy wisdom about carriage bolts. Welcome to darlenemccoy.com, where you’ll find the sweetest tips and tricks for your DIY projects.

Today, we’re talkin’ ’bout the different types of carriage bolts and what sets ’em apart.

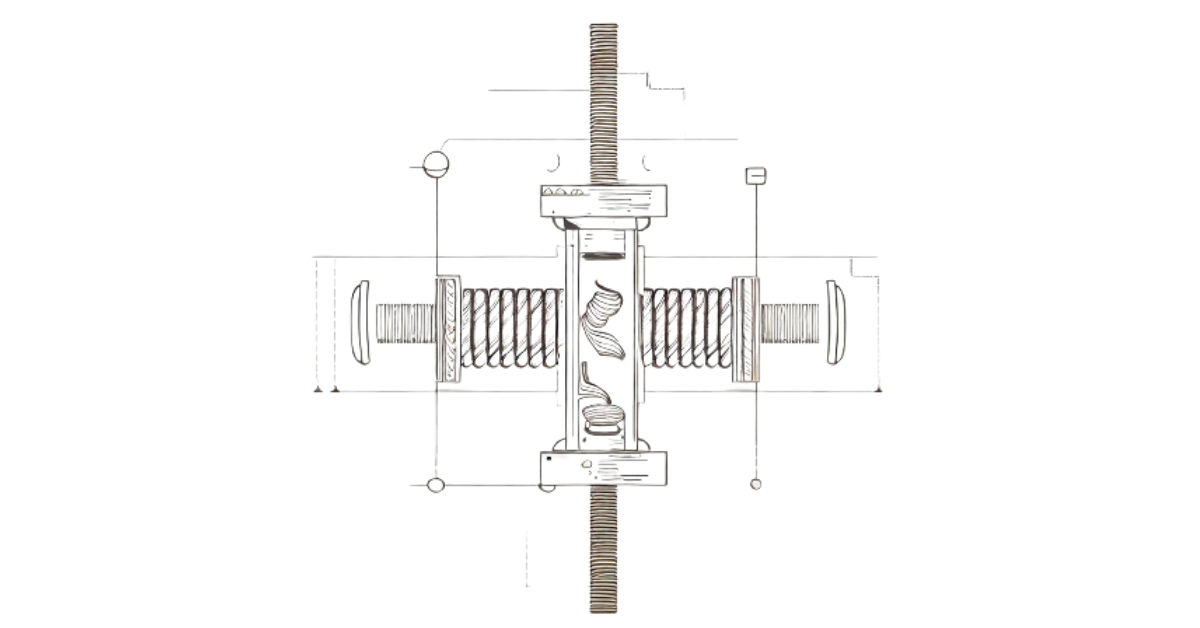

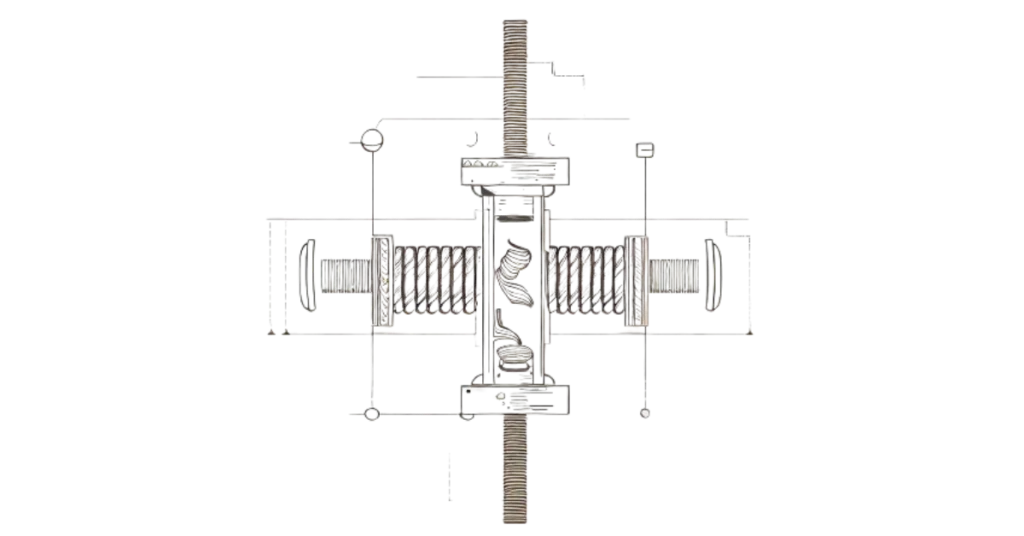

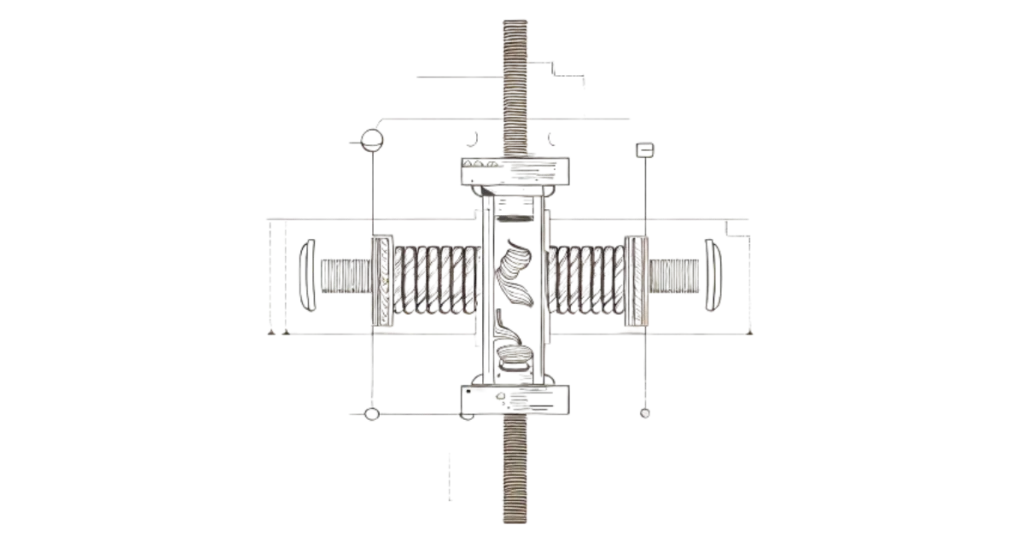

Carriage bolts, my friends, they’re a special kind of fastener with a round head and a square neck beneath. The trick is, they won’t go twistin’ and turnin’ when you tighten ’em up. That’s why they’re perfect for projects where you can only access one side of the bolt. You might know ’em as plow bolts or coach bolts, and they’re just what you need to join wood, metal, plastic, and more together.

But did you know there’s more to carriage bolts than meets the eye? There’s a whole world of ’em out there, with different materials, sizes, shapes, and finishes. Each type’s got its own advantages, disadvantages, and special uses. Today, we’re gonna dive deep into the blues of carriage bolts. Here’s what we’ll cover:

- The four main types of carriage bolts: roundhead and rib-necked bolts, roundhead and short-necked bolts, flathead and square-necked bolts, and fin necked bolts.

- The features and functions of each type of carriage bolt.

- The common uses and examples of each type of carriage bolt.

By the time we’re through, you’ll be strummin’ along with the perfect carriage bolt for your project. Let’s pick up them bluesy notes and get started!

The Four Main Types of Carriage Bolts

Now, before we start croonin’ ’bout the types, let’s give a nod to the search results¹²³⁴. They tell us there are four main types of carriage bolts you’ll find out there:

Roundhead and Rib-Necked Bolts

This type, oh, it’s got a round head with ribs or serrations underneath. Them ribs, they get a good grip on the material, keepin’ everything tight against vibrations and movin’. You’ll find these bolts rockin’ in wood-to-wood connections.

Roundhead and Short-Necked Bolts

Here, you got that same round head, but this time, there’s a short square neck under it. That neck, it’s shorter than the diameter of the shank. So, where do these bolts shine? Well, they’re perfect for metal-to-metal connections or in places where a longer neck’d mess with your design.

Flathead and Square-Necked Bolts

Now, take a gander at these fellas! You got a flat or countersunk head with a square neck underneath. The head, it’s all flush with the material’s surface. So, where do you use these? When you need a smooth finish or when there’s hardly any space for a round head.

Fin Necked Bolts

Last but not least, these bolts sport a round head with fins or projections underneath. Them fins, they get a good grip on plastic or composite materials, keepin’ everything from twistin’ and turnin’.

Each of these types of carriage bolts brings its own groove and style, fittin’ just right in different situations. Now, let’s jam along and look at each type a bit closer.

The Features and Functions of Each Type of Carriage Bolt

Now, let’s get into the heart of these bluesy carriage bolts. Here’s what sets each type apart:

Roundhead and Rib-Necked Bolts

These bolts, my friends, they got a smooth, round head sittin’ all flat on the material. Underneath, there’s a square neck slidin’ into a square hole or recess. You know what that neck does? Keeps your bolt from turnin’ when you tighten up the nut. And them ribs or serrations? They got the magic touch, gettin’ a good grip on the material, keepin’ it all nice and tight. And here’s the kicker, these bolts are self-lockin’, so you only need one wrench or tool to install ’em from the opposite end. Ain’t that somethin’?

Roundhead and Short-Necked Bolts

Alright, let’s move along to this type. Smooth, round head sittin’ all flat on the material, just like before. And you know what’s underneath? A short square neck, slidin’ into a square hole or recess, just like before. But here’s the twist, that neck’s shorter than the diameter of the shank. So where do these bolts shine? When you’re workin’ with thinner materials or when a longer neck’d mess with your design. And guess what? These bolts are self-lockin’ too, just like their rib-necked buddies.

Flathead and Square-Necked Bolts

Oh, these bolts got style! Flat or countersunk head, sittin’ all flush with the material’s surface. And underneath? A square neck, slidin’ into a square hole or recess. Man, that flat head’s got somethin’ to show off. It creates a smooth, seamless finish, no snaggin’ or scratchin’ when you’re workin’ with ’em. And of course, they’re self-lockin’ too, just like their cousins.

Fin Necked Bolts

And now, for our last type. Smooth, round head sittin’ all flat on the material, just like the rest. But them fins or projections underneath, they’re the secret. They fit into grooves or slots in plastic or composite materials, gettin’ a good grip and keepin’ everything in place. And yep, you guessed it, these bolts are self-lockin’ too, just like the others.

The Common Uses and Examples of Each Type of Carriage Bolt

Now that we’re feelin’ the rhythm of each type of carriage bolt, let’s see where they shine and how they fit in different projects. I’ll give you some examples to get your bluesy soul goin’:

Roundhead and Rib-Necked Bolts

These fellas, they’re the go-to choice for wood-to-wood connections. Think furniture, decks, docks, fences, playground equipment, and more. They create a strong and stable connection between the wood parts of your project. And hey, they can even add a little contrast or complement the color and texture of the wood.

Roundhead and Short-Necked Bolts

Now, let’s move on to this type. They’re a real hit in metal-to-metal connections, like in automotive, electrical, or industrial applications. These bolts keep your metal components secure, preventin’ ’em from loosening or shiftin’ when things get shaky. And of course, they got that smooth and sleek finish, makin’ your project look real good.

Flathead and Square-Necked Bolts

Ain’t they just the lookers? These bolts love it when there’s a need for a smooth finish or when space is scarce for a round head. Think structural engineering, architectural design, or furniture makin’. They create a flush and seamless connection between your materials, preventin’ any crackin’ or splittin’ when the pressure’s on. And here’s the best part, they got that tamper-proof clamping force, keepin’ your project safe and sound.

Fin Necked Bolts

Last but not least, these bolts know their way ’round plastic or composite materials. Think locks, hinges, gates, signs, or machinery. They grip the material real good, preventin’ any unwanted twistin’ and turnin’. And guess what? They’re rust-proof and ready to take on whatever life throws their way.

Conclusion

There you have it, folks, the blues of carriage bolts! They come in different types, each bringin’ their own style and groove to the stage. We got the roundhead and rib-necked bolts, struttin’ their stuff in wood-to-wood connections. The roundhead and short-necked bolts, rockin’ it out in metal-to-metal connections. The flathead and square-necked bolts, smooth and stylish, with their flush finish. And last but not least, the fin necked bolts, grippin’ it tight in plastic or composite materials.

Each type’s got its own charm, its own advantage, and its own place in the project. So, when you’re pickin’ the right carriage bolt for your bluesy project, remember to choose the type that matches the rhythm of your job. And with that, I hope you’re feelin’ the soul of carriage bolts deep down in your DIY heart.

If you got any questions or stories ’bout carriage bolts, I’d love to hear ’em. Drop ’em down below, and we’ll keep the bluesy conversation goin’.

Thanks for joinin’ the jam session, folks!